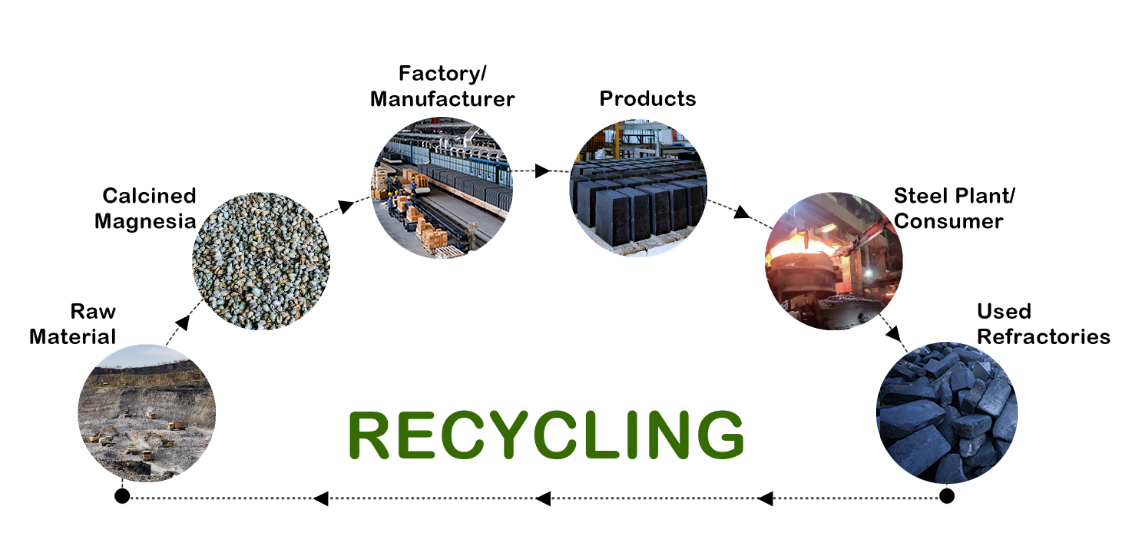

Our company is committed to prioritizing the substantial quantities of spent refractories generated by the steel and non-ferrous metal industry in the future. Recognizing the imperative to reduce CO2 emissions considering escalating energy costs and environmental concerns, we have decided to collaborate with steelworks in China. Our initiative involves reclaiming demolished refractories post-usage in various vessels and furnaces. Through employing specialized processing methods, our company aims to recover a significant percentage of raw materials from these spent refractories. We are dedicated to fostering a sustainable manufacturing process, with a focus on minimizing industrial waste. Spent refractory materials still hold considerable value as raw materials. The escalating prices and supply challenges associated with high-quality virgin raw materials serve as a compelling motivation for embracing a closed-loop refractory recycling approach.

Demolished MgO-C bricks

Recycled material from MgO-C bricks

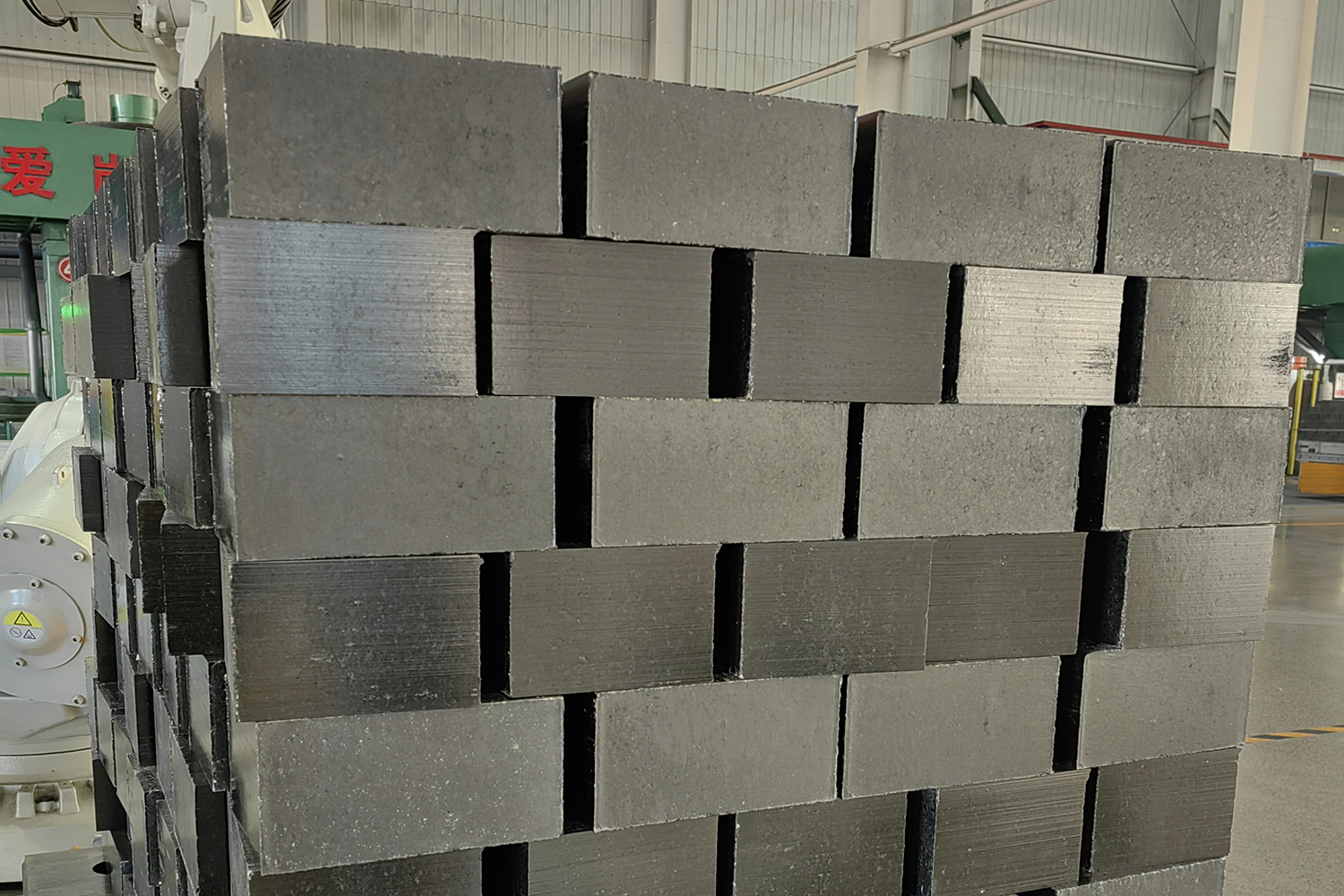

New manufactured MgO-C bricks with a large amount of recycled raw material