Lincem produces caustic and dead burnt magnesia sourced from a magnesite mine in the Haicheng area of Northern China. Magnesia, known for its high temperature resistance (> 2800°C), is an ideal raw material for the refractory industry. However, the magnesium carbonate extracted from the quarry has to undergo a thermal process before becoming suitable for refractory applications. Lincem conducts these specific burning processes in its facilities located in Haicheng, Liaoning Province, and Zibo, Shandong Province, China. The thermal processing based on the temperature gradient of magnesite.

Caustic magnesia (CCM) is produced by burning at temperatures around 800 to 1000℃, retaining a residual amount of carbonate in the crystal lattice. This type of magnesia is reactive compared to sintered or fused magnesia. Caustic magnesia finds applications in construction and the chemical industry, and is used in agriculture to adjust soil pH levels.

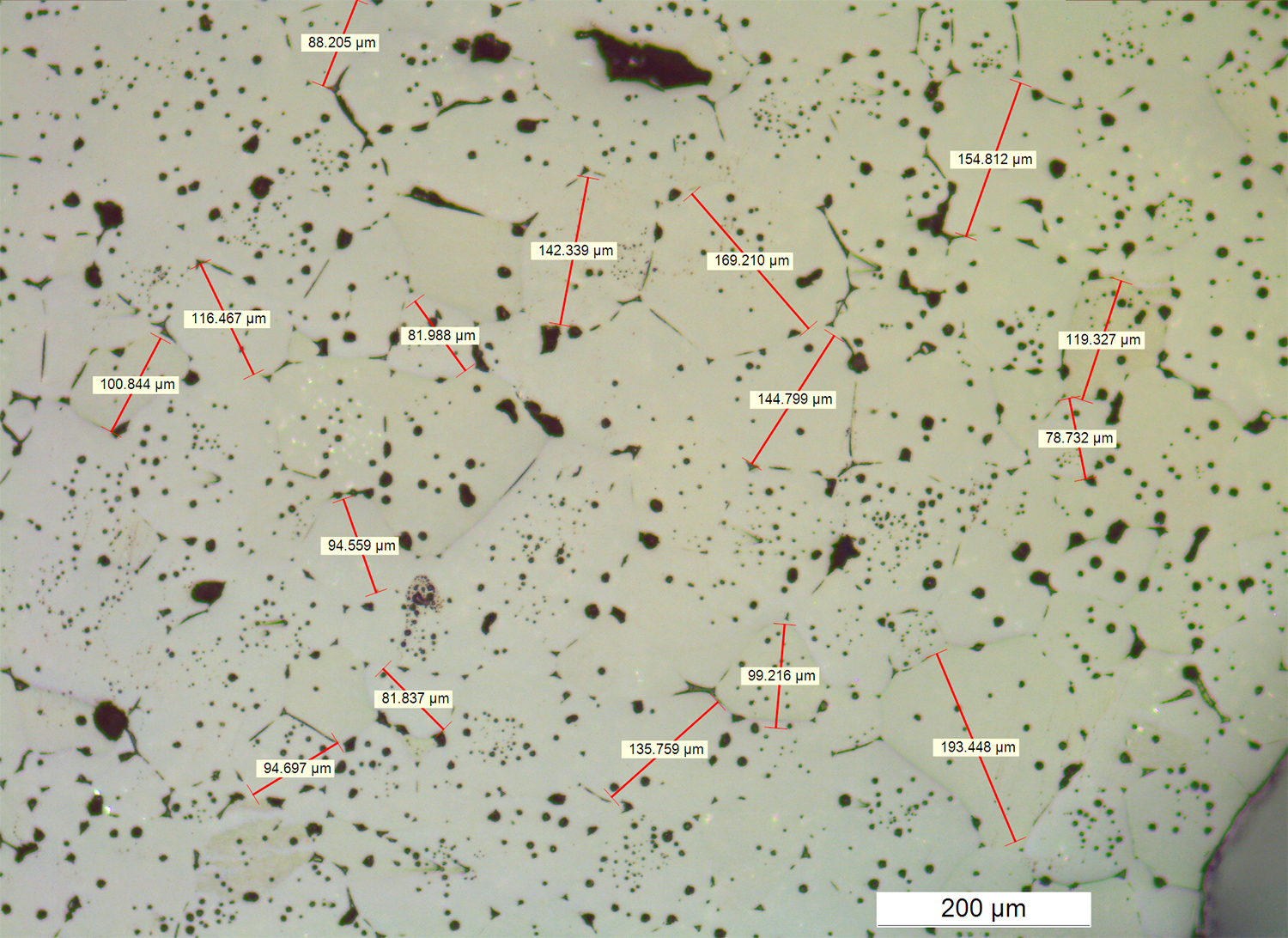

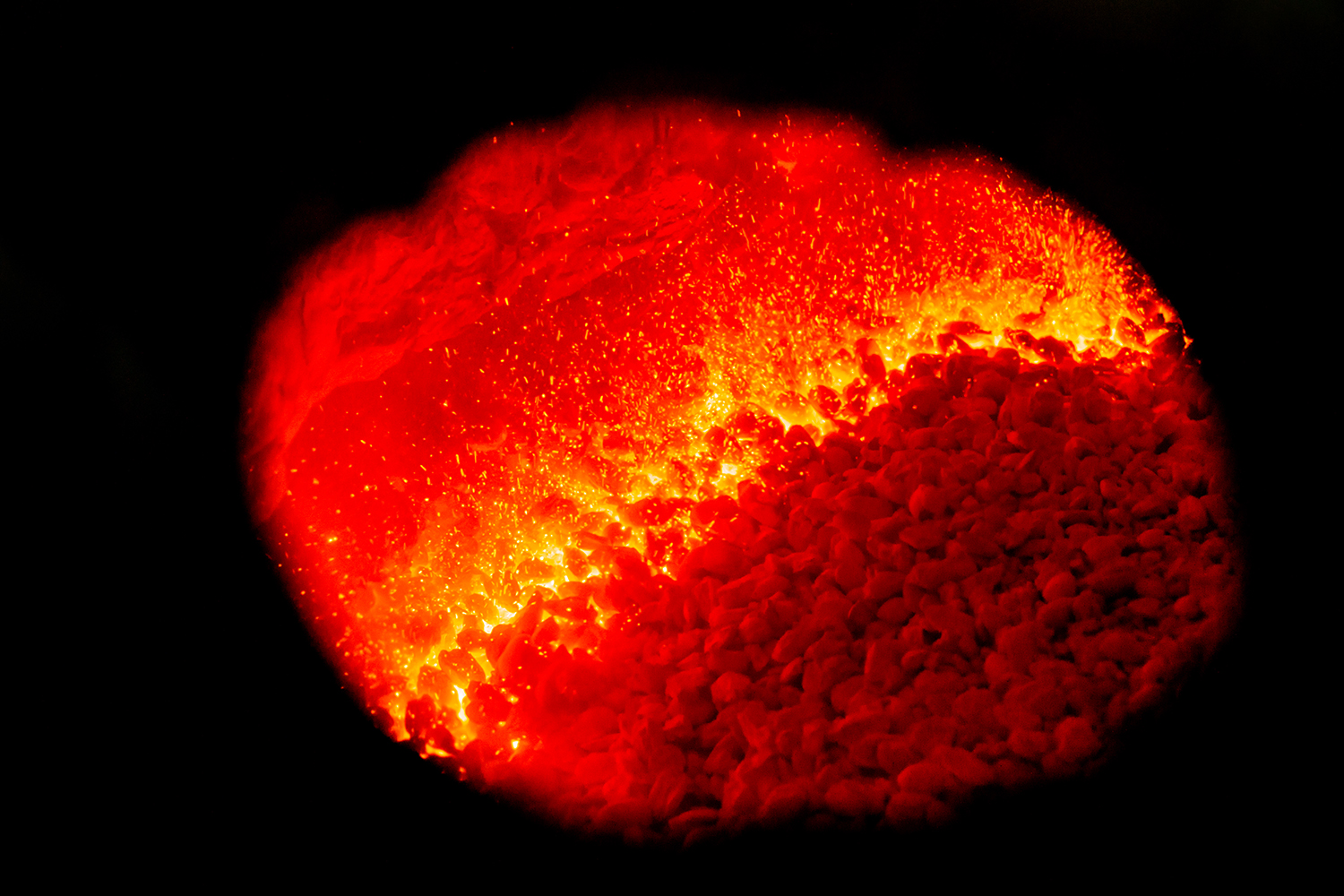

On the other hand, sintered magnesia, also known as dead burnt magnesia (DBM), undergoes a higher thermal treatment, reaching approximately 1800℃ until it loses reactivity. Sintering results in a crystalline status of MgO, providing exceptional properties. Lincem offers DBM in various product classes, ranging from 90% to 97.5% MgO. DBM is manufactured from natural magnesite ore and sintered in a high-temperature shaft kiln fired by liquid gas.

The high-grade sintered magnesia produced by Lincem is an excellent raw material for refractory manufacturers, offering superior thermal resistance suitable for applications in the steel, cement and non-ferrous metal industries. Lincem’s commitment to quality ensures the sintered magnesia it produces stands as the best-qualified raw material for the refractory industry.

This topic is currently undergoing further development and will be updated in near future. Stay tuned for additional information and insights on this subject.